As a professional in manufacturing, leveraging advanced technologies like polymer powder bed 3D printing can transform your production processes, offering enhanced efficiency, cost savings, and superior product quality. This guide delves into the essential aspects of investing in polymer powder bed 3D printing, providing you with actionable insights to make an informed decision.

What is powder bed 3D printing

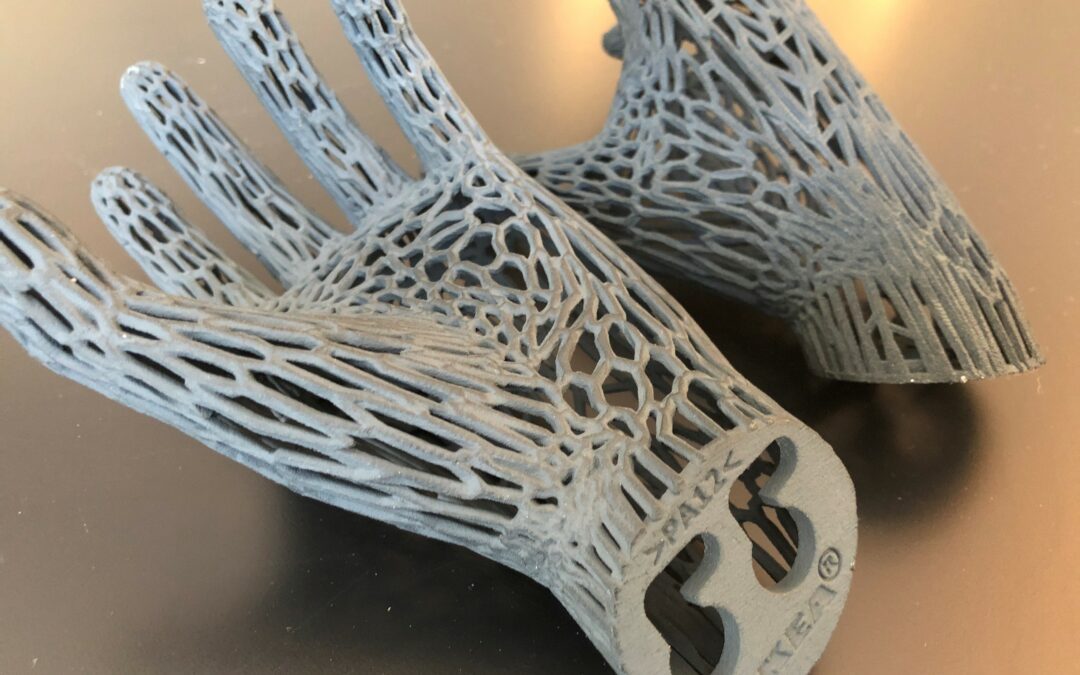

Polymer powder bed 3D printing, commonly referred to as selective laser sintering (SLS), uses a laser to fuse polymer powder layer by layer into a solid object. This technology is highly valued for its ability to create complex, durable, and lightweight parts with excellent surface finishes and mechanical properties.

What are the benefits of powder bed 3D printing

Complex geometries: Capable of producing intricate designs with high precision.

Material efficiency: Reduces waste by using only the necessary amount of material.

Customization: Ideal for producing customized parts on-demand.

Strength and durability: Produces robust parts with excellent mechanical properties.

What should I think of before investing in a powder bed 3D printer

1. Application requirements

Defining your application requirements is crucial before investing in polymer powder bed 3D printing:

Material Compatibility: Determine the specific polymers you will be using, such as nylon, polyamide, or TPU.

Part Size and Volume: Assess the dimensions and production volumes of the parts you need to print.

Surface Finish and Detail: Identify the required level of surface finish and detail for your parts.

Mechanical Properties: Ensure the parts meet the necessary strength, flexibility, and durability standards.

2. Printer specifications

Evaluate the specifications of different polymer powder bed 3D printers:

Build Volume: Ensure the printer can accommodate the size of the parts you intend to produce.

Resolution and Precision: Higher resolution and precision are critical for detailed and complex parts.

Print Speed: Consider the printing speed, especially if you need to produce high volumes.

Material Handling: Check how the printer handles different polymers and the ease of material changeover.

3. Cost analysis

Conduct a thorough cost analysis to understand the financial implications:

Initial Purchase Cost: The upfront cost of the polymer powder bed 3D printer.

Operational Costs: Ongoing expenses such as polymer powder costs, energy consumption, and maintenance.

Post-Processing Costs: Costs associated with post-processing steps like cleaning, finishing, and any necessary heat treatment.

Return on Investment (ROI): Calculate the potential ROI by comparing the costs with the expected benefits in terms of production efficiency and product quality.

4. Material considerations

Choosing the right polymer material is essential:

Nylon: Known for its strength, flexibility, and durability, suitable for a wide range of applications.

Polyamide: Offers excellent mechanical properties and is ideal for functional prototypes and end-use parts.

TPU (Thermoplastic Polyurethane): Provides flexibility and resilience, suitable for applications requiring elasticity.

Ensure the printer you choose supports the polymers you need and provides reliable material handling and storage solutions.

5. Software and workflow integration

The software ecosystem is an integral part of the 3D printing workflow:

CAD Software Compatibility: Ensure the printer is compatible with your existing CAD software.

Slicing Software: Evaluate the capabilities of the slicing software, which converts 3D models into printable layers.

Workflow Integration: Assess how the printer will integrate into your existing manufacturing workflow and any additional software required for managing and monitoring the printing process.

6. Support and training

Reliable support and training are essential:

Manufacturer Support: Ensure the printer manufacturer provides comprehensive support, including troubleshooting and maintenance.

Training Programs: Look for training programs that can help your team get up to speed with the new technology.

Community and Resources: Access to a user community and online resources can be invaluable for troubleshooting and optimizing your processes.

7. Regulatory and safety considerations

Compliance with industry standards and safety regulations is critical:

Regulatory Compliance: Ensure the printer and materials comply with relevant industry standards and certifications.

Safety Features: Evaluate the safety features of the printer, such as enclosed build chambers, filtration systems, and emergency shutoff mechanisms.

Environmental Impact: Consider the environmental impact of the printer and materials, including waste disposal and energy consumption.

How do I research the right powder bed 3D printer

1. Industry research

Conduct thorough industry research to identify the most reputable and reliable polymer powder bed 3D printers:

Industry Reports and Reviews: Read reports and reviews from reputable industry analysts and publications.

Case Studies: Look for case studies of companies that have successfully implemented polymer powder bed 3D printing.

Webinars and Conferences: Attend webinars and industry conferences to learn about the latest advancements and network with experts.

2. Vendor comparison

Compare different vendors and their offerings:

Reputation and Experience: Choose vendors with a strong reputation and extensive experience in the industry.

Product Portfolio: Evaluate the range of products offered by each vendor and their suitability for your applications.

Customer Support: Assess the quality and availability of customer support and service.

3. Technical evaluation

Conduct a technical evaluation of the shortlisted printers:

Benchmark Testing: Request benchmark tests to evaluate the performance and quality of the printers.

Sample Parts: Ask for sample parts to assess the surface finish, precision, and mechanical properties.

Factory Visits: If possible, visit the manufacturer’s facility to see the printers in action and assess their production capabilities.

4. Total cost of ownership (TCO)

Calculate the total cost of ownership to understand the long-term financial commitment:

Initial Investment: Include the cost of the printer, installation, and any necessary infrastructure upgrades.

Operational Costs: Factor in polymer powder costs, energy consumption, maintenance, and labor.

Depreciation and Resale Value: Consider the depreciation of the printer over time and its potential resale value.

5. Future-proofing your investment

Ensure your investment is future-proof by considering the following:

Scalability: Choose a printer that can scale with your production needs.

Upgradability: Look for printers that offer upgrade options for hardware and software.

Industry Trends: Stay informed about industry trends and advancements to ensure your investment remains relevant.

Conclusion

Investing in polymer powder bed 3D printing is a strategic decision that can significantly enhance your manufacturing capabilities. By carefully considering your application requirements, evaluating printer specifications, conducting a thorough cost analysis, and researching vendors and industry trends, you can make an informed decision that aligns with your production goals and budget. Prioritize support, training, and regulatory compliance to ensure a smooth integration of the new technology into your manufacturing workflow.

Polymer powder bed 3D printing holds immense potential for innovation and efficiency in manufacturing. By following the guidelines in this comprehensive guide, you will be well-equipped to select the right solution and unlock the full potential of additive manufacturing for your company.