Powder bed 3D printing has become indispensable across various high-stakes industries. These sectors demand exceptionally clean and high-quality 3D printed parts due to stringent performance, safety, and regulatory requirements. Here, we explore the industry verticals where cleanliness in powder bed 3D printing is paramount and explain why it matters.

Aerospace

Why Clean Parts Matter:

- Performance and Safety: Aerospace components must meet stringent safety and performance standards. Contamination can lead to part failure, potentially causing catastrophic consequences.

- Regulatory Compliance: The aerospace industry is heavily regulated, with strict standards for material properties, surface finish, and cleanliness. Ensuring that 3D printed parts are free from contaminants is essential to meet these regulations.

In the aerospace industry, even minor imperfections can have significant repercussions. The meticulous cleaning of 3D printed parts ensures they function flawlessly under extreme conditions, maintaining the integrity of aircraft and spacecraft.

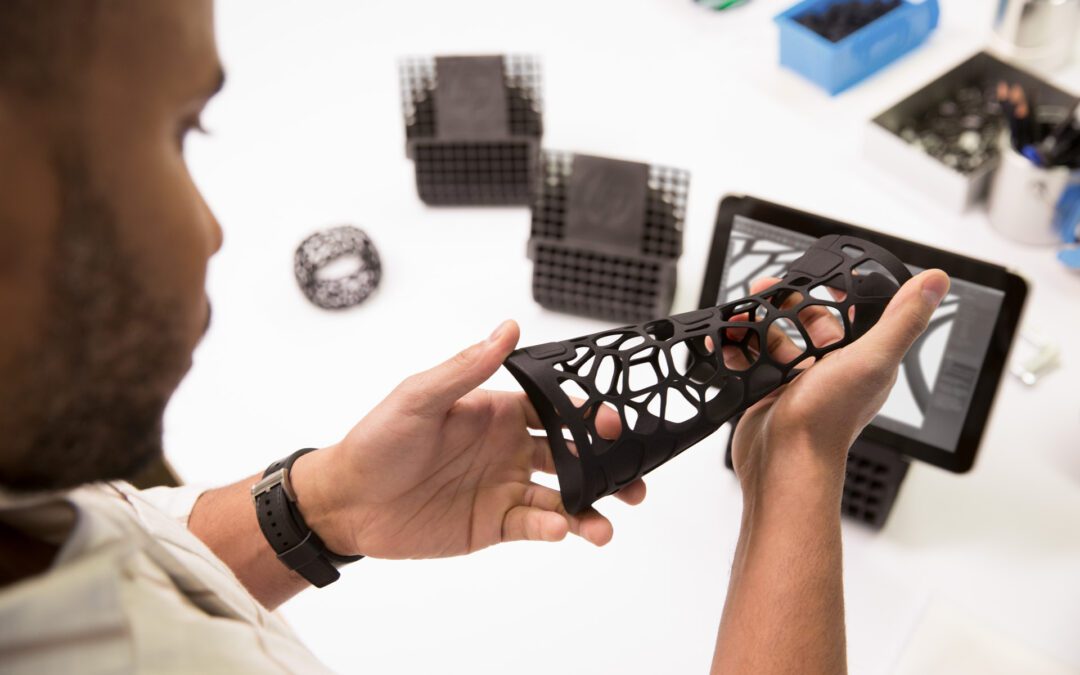

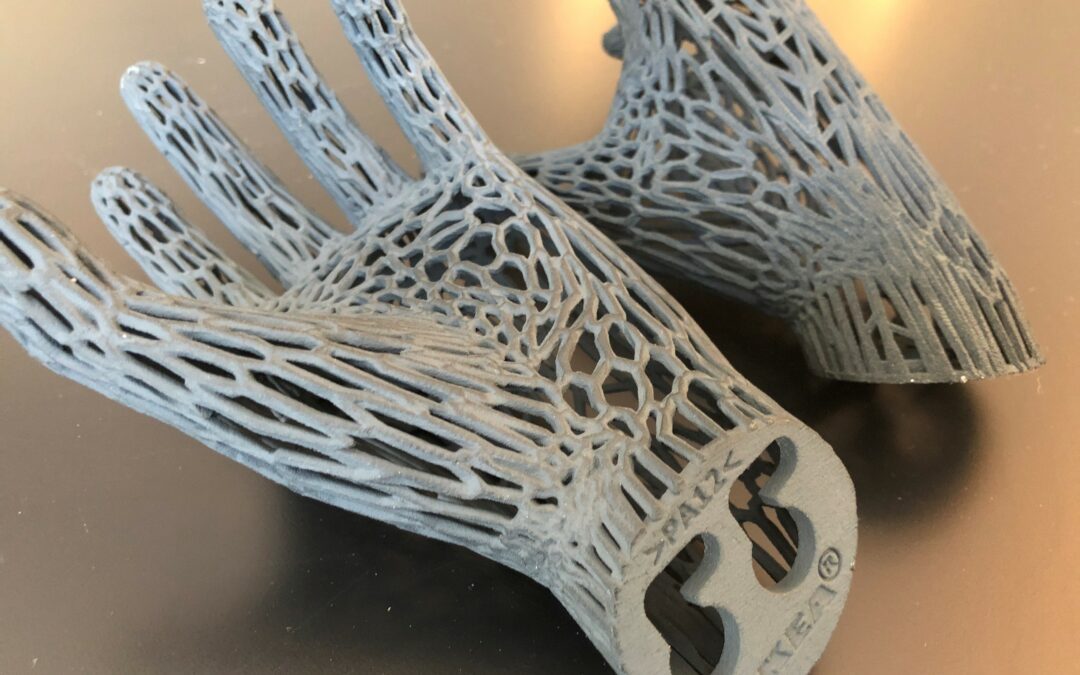

Medical and healthcare

Why Clean Parts Matter:

- Sterility: Medical implants and devices must be sterile to prevent infections. Any residual powder or contaminants can compromise the sterility of the parts.

- Biocompatibility: Clean surfaces are crucial to ensuring that 3D printed parts do not induce adverse reactions in the human body.

- Precision: Medical devices often require precise geometries and smooth surfaces, necessitating thorough cleaning post-printing.

In the medical sector, the stakes are incredibly high. Cleanliness ensures that implants and devices not only fit perfectly but also do not pose any health risks to patients. The demand for clean and precise medical devices is driving significant growth in the 3D printing market, projected to reach USD 3.5 billion by 2026 according to Grand View Research.

Automotive

Why Clean Parts Matter:

- Functional Integrity: Automotive parts, especially those related to engine components and safety systems, must be free of defects and contaminants to function properly.

- Durability and Performance: Clean parts contribute to the longevity and reliability of automotive components, which are subject to harsh conditions and stresses.

- Aesthetic and Functional Finish: Both aesthetic appeal and functional finish are crucial, particularly in custom interiors and high-performance components.

The automotive industry is increasingly adopting 3D printing to produce lightweight and high-performance parts. Cleanliness in these parts ensures they perform reliably under the demanding conditions vehicles often face.

Consumer electronics

Why Clean Parts Matter:

- Miniaturization and Precision: The trend towards smaller and more complex electronic components requires extremely clean and precise parts to ensure proper assembly and functionality.

- Heat Dissipation: Clean surfaces are essential for effective heat dissipation in electronic components, impacting performance and longevity.

- Aesthetic Quality: High aesthetic standards mean that any surface imperfections due to residual powder or contaminants are unacceptable.

Consumer electronics rely on the miniaturization and precision of components. Clean 3D printed parts are vital for the performance and aesthetic quality of these devices, meeting consumer expectations and technical requirements.

Dental industry

Why Clean Parts Matter:

- Fit and Comfort: Dental implants and orthodontic devices must fit perfectly and be comfortable for patients. Clean, precise parts ensure these requirements are met.

- Sterility: Sterility is paramount in dental applications to prevent infections.

- Material Properties: Residual powder can affect the material properties and performance of dental devices, necessitating thorough cleaning.

In the dental industry, the cleanliness of 3D printed parts is critical to patient satisfaction and safety. Ensuring sterility and precision in dental implants and devices enhances their effectiveness and comfort.

Why cleanliness is critical

Functional Performance: Residual powders and contaminants can interfere with the mechanical properties and performance of printed parts.

Aesthetic Requirements: Surface finish is important for both functional and aesthetic reasons, particularly in consumer electronics and automotive industries.

Regulatory Compliance: Many industries have strict regulatory standards mandating high levels of cleanliness and quality assurance.

Health and Safety: In medical and dental applications, the health and safety of patients are directly impacted by the cleanliness of the parts.

Conclusion

Powder bed 3D printing is deeply changing multiple high-stakes industries by providing precise and customizable parts. However, the cleanliness of these parts is non-negotiable. Aerospace, medical, automotive, consumer electronics, and dental industries all demand exceptionally clean parts to meet stringent performance, safety, and regulatory requirements. By understanding the importance of cleanliness and implementing rigorous post-processing techniques, manufacturers can ensure their 3D printed parts meet the highest standards of quality and reliability.

The growing adoption of 3D printing across these industries highlights the need for continued innovation in post-processing techniques to achieve the required cleanliness. As the technology advances, the ability to produce clean, high-quality parts will remain a critical factor in the success of powder bed 3D printing.

By focusing on the critical need for clean parts in high-stakes industries and highlighting the importance of meticulous post-processing, this blog post provides valuable insights for businesses looking to leverage powder bed 3D printing technology. Ensuring optimal cleanliness not only meets regulatory and safety standards but also enhances the overall performance and reliability of 3D printed parts, making it a key consideration in the future of manufacturing.

IMAGE: Anna Zvereva, CC BY-SA 2.0