This article explores the latest advancements in polymer powder bed 3D printer technology, highlighting the innovations that are transforming manufacturing processes across various industries.

Why you should read this article:

- Discover the latest materials enhancing 3D printing capabilities

- Learn about innovations that are boosting printing speed and efficiency

- Understand how AI and machine learning are optimizing 3D printing

- Explore sustainable practices and materials in 3D printing

- See how these advancements are expanding applications across industries

Improved material properties

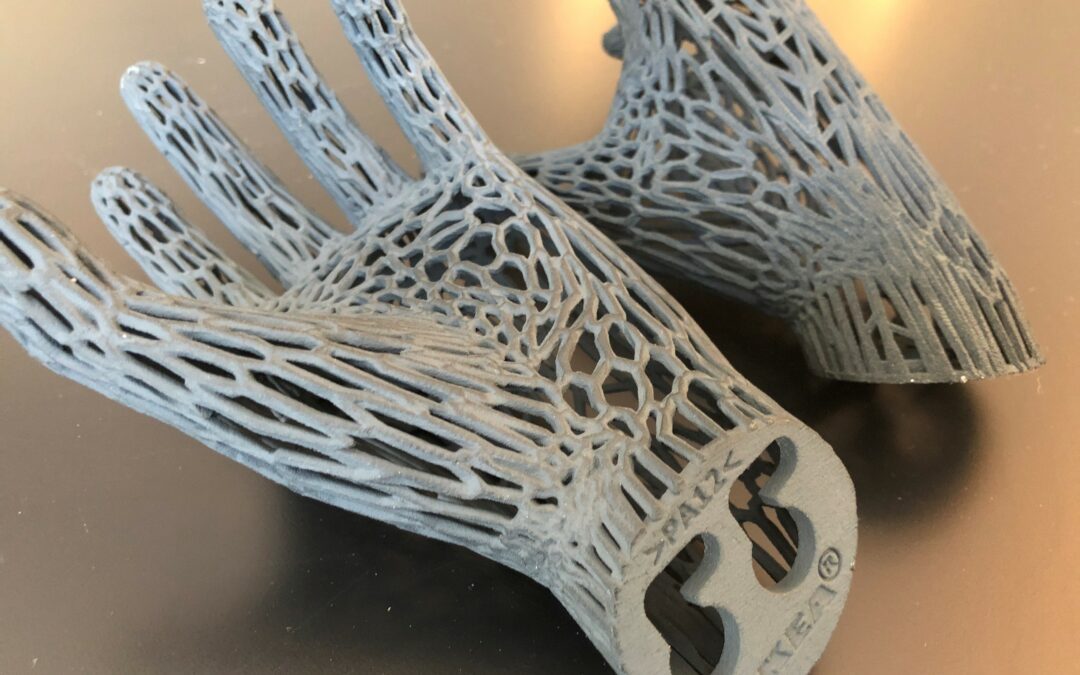

One of the most significant advancements in polymer powder bed 3D printing is the development of new and improved materials. Researchers and manufacturers are now producing polymers with enhanced mechanical properties, thermal stability, and chemical resistance. These new materials broaden the scope of applications, making it possible to create more durable and high-performance parts.

Enhanced printing speed

Recent innovations have focused on increasing the speed and efficiency of polymer powder bed printers. High-speed sintering (HSS) is one such advancement that uses infrared lamps instead of lasers to fuse the powder, significantly reducing print times. Additionally, multi-laser systems and improved scanning algorithms are being integrated into machines to enhance productivity without compromising quality.

Higher resolution and surface finish

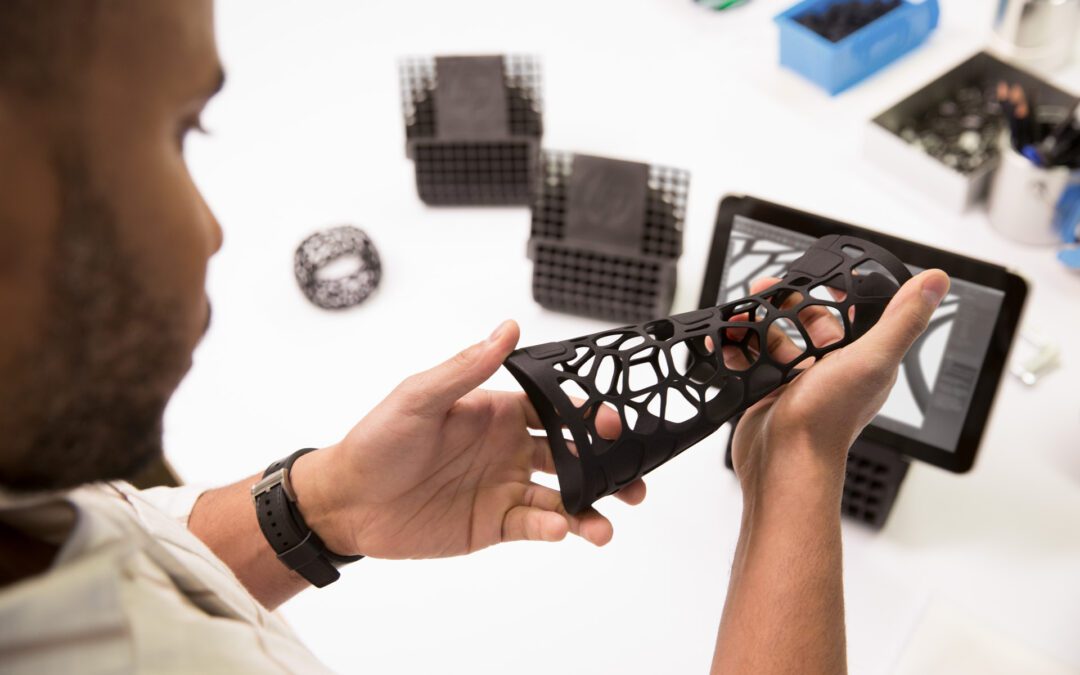

The push for higher resolution and better surface finishes has led to the development of advanced laser systems and more refined powder materials. New printers can achieve finer layer thicknesses, resulting in smoother surfaces and more detailed prints. This is particularly beneficial for applications in the medical and aerospace industries, where precision is paramount.

Automated post-processing

Post-processing is a critical step in the 3D printing workflow, often requiring significant manual labor. However, new automated post-processing solutions are emerging, including depowdering systems and automated surface finishing. These innovations reduce the time and effort needed to prepare parts for use, making the overall process more efficient and cost-effective.

Integration of AI and machine learning

Artificial intelligence (AI) and machine learning are playing an increasingly important role in polymer powder bed 3D printing. These technologies are being used to optimize print parameters, predict and prevent failures, and improve the overall quality of printed parts. AI-driven software can analyze vast amounts of data to identify patterns and make real-time adjustments, leading to more reliable and consistent prints.

Sustainable and recyclable materials

Sustainability is a growing concern in the manufacturing industry, and polymer powder bed 3D printing is no exception. The latest advancements include the development of recyclable powders and more sustainable printing processes. Manufacturers are now focusing on reducing waste and creating eco-friendly materials that maintain high performance standards.

Expansion of industrial applications

As polymer powder bed technology advances, its applications are expanding across various industries. The automotive, aerospace, healthcare, and consumer goods sectors are increasingly adopting this technology for both prototyping and end-use production. The ability to produce lightweight, strong, and complex parts on-demand is revolutionizing manufacturing processes and reducing time-to-market for new products.

Conclusion

Polymer powder bed 3D printing technology is rapidly advancing, driven by innovations in materials, speed, precision, and sustainability. These advancements are opening up new possibilities for manufacturers, enabling the production of high-quality parts with unprecedented efficiency and detail. As research and development continue, we can expect even more groundbreaking developments in this exciting field.